Specs: |

| Rotation speed: 3000-12000r/min |

Work voltage: 12-48VDC |

| Power: 400W |

Torque: 500mN.m |

| Insulation resistance: >2Megohm |

Dielectric strength: 400V |

| Motor Length: 186mm |

Diameter: 52mm |

| Axis collet Length: 48mm |

Diameter of Axis collect holder: 16mm |

| Repeat accuracy: 0.01-0.03mm |

ER11 collect: 3.175mm |

| Air cooled |

Soft-start function |

| Motor Controller |

Mounting Bracket |

| Includes potentiometer for manual control |

Nema23 stepper motor, 1.9 Nm |

| Hall Effect limit switches |

Touch off plate |

| 6"-7" of Z-axis travel |

Included Accessories: |

| ER11 1-7mm & 2x 1/8" & 1/4" (16 total collets) |

5x 4 Flute HSS Solid Carbide End Mill |

| 4 Flute HSS Straigh Shank End Mill 1.5-6mm (10 end mills) |

Images: |

|

|

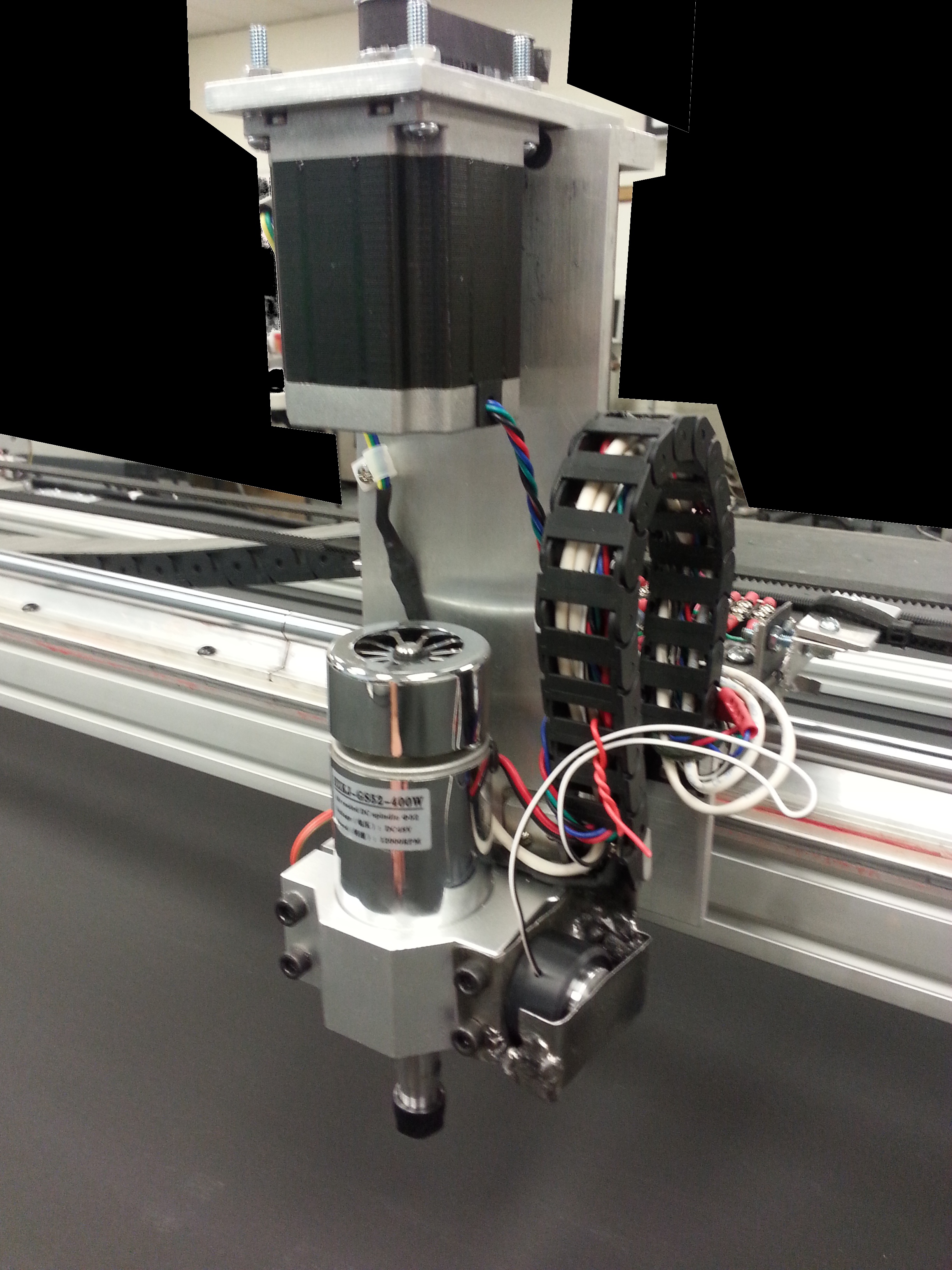

| This shows a close up of the milling head attached to the gantry. There are only 2 bolts and 2 screws to attach it to the X-axis, plus some electrical connections. |

Here's a view of the electrical connections. I will eventually be making this a plug-in style. |

|

|

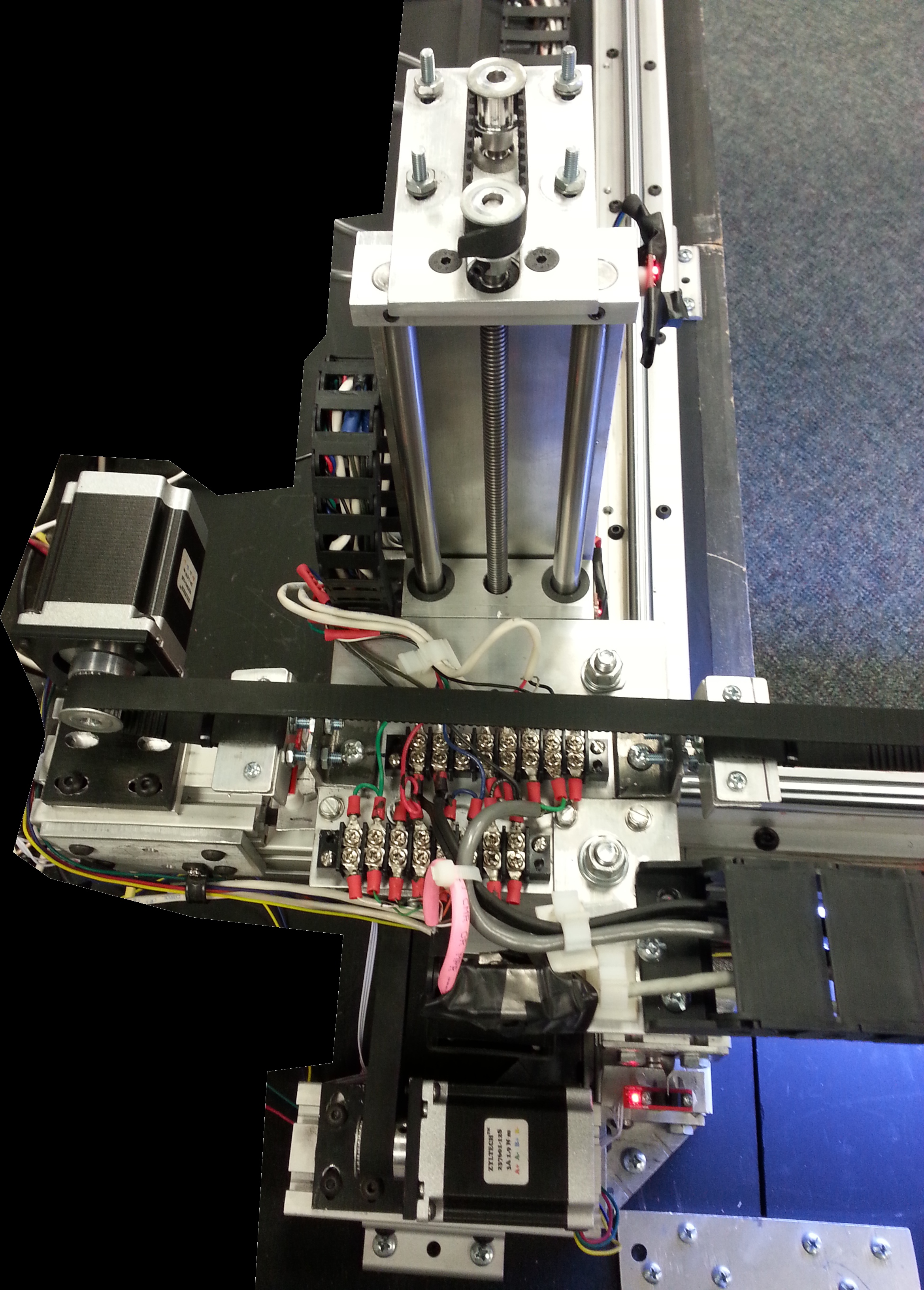

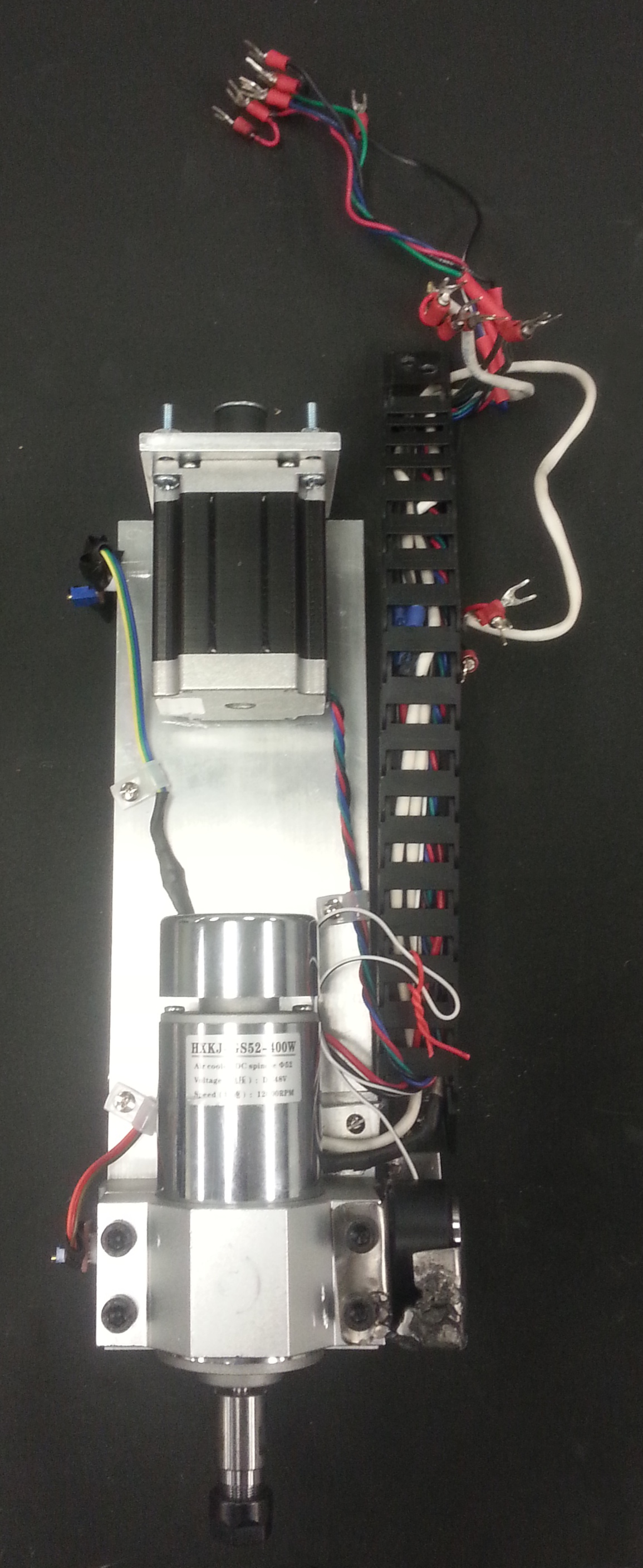

| This is the milling head on it's own, showing all the wires that come out of the drag chain. |

This side view shows just how thin the head it. It's not much thicker than the motor and motor mount. |

|

|

| Here's a picture of all the milling bits and collets I'm including. |

This box is too small for all the bit and collets I'm including, so I'm including a larger box built in the same way. |

|

|

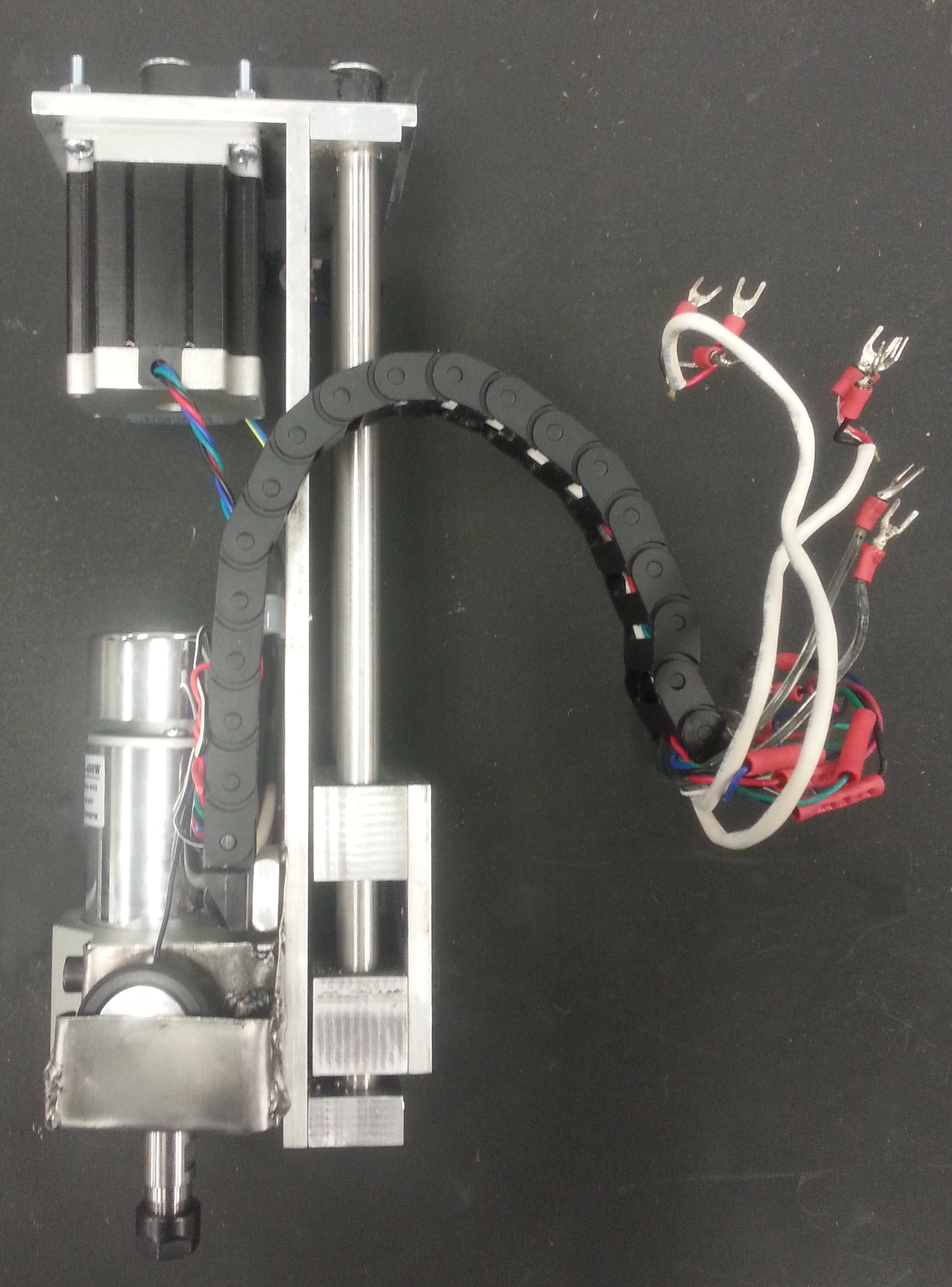

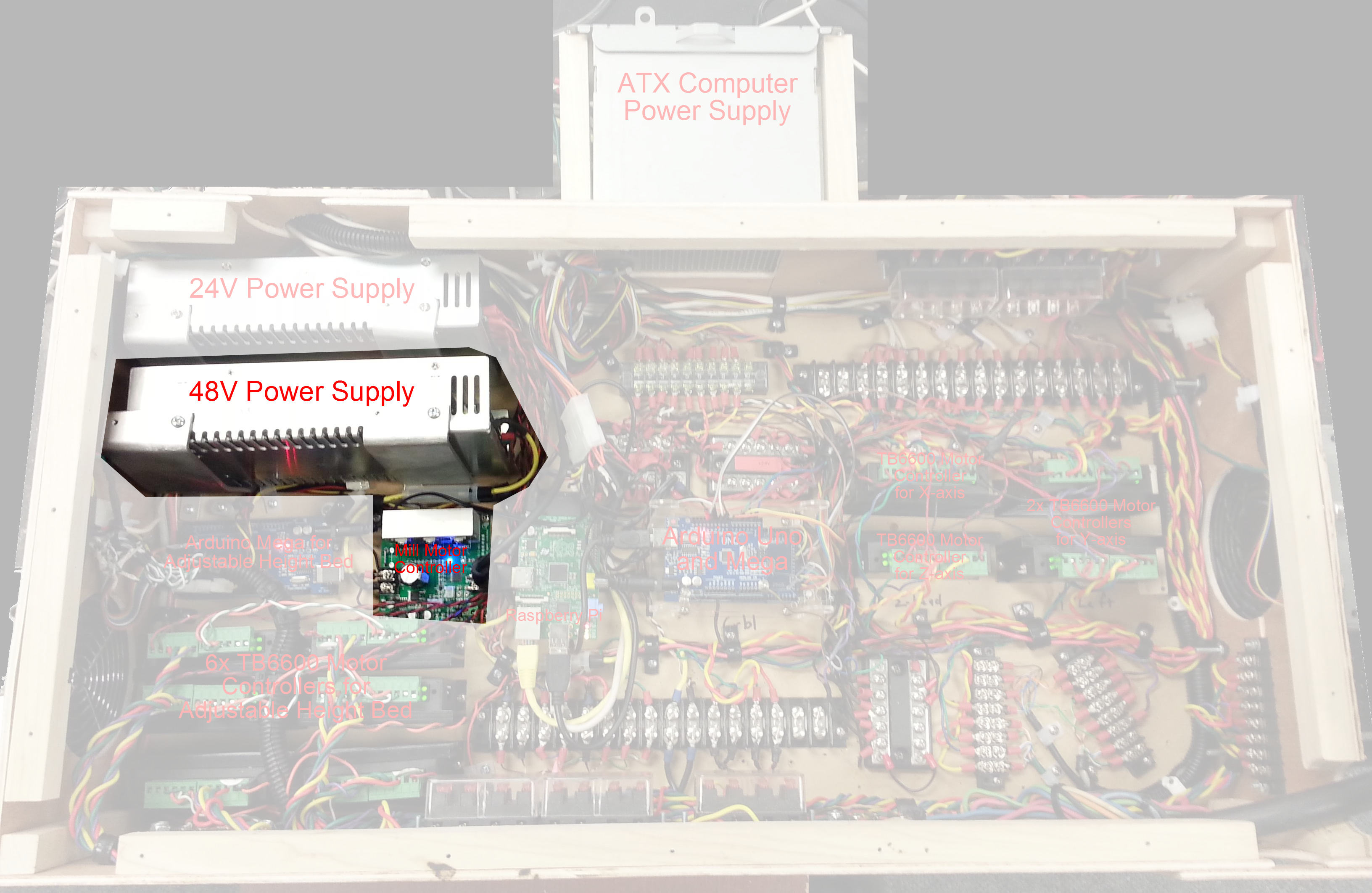

| This is all that's needed for electronics, to be added to the control box for using the milling head. The Nema23 will be controlled by one of the motor controllers already installed. |

Here's a picture of all the milling bits and collets I'm including. |

|